WIRE DRAWING MACHINES

Wire drawing is one of the core processes in modern wire and cable manufacturing. It involves reducing the wire’s diameter while increasing its length, typically through multiple drawing stages. In the production of ultra-fine wires made from copper, aluminum or special alloys, the wire passes through high-precision tooling systems including drawing dies, cones, rollers and guide components, often combined with thermal treatments such as annealing.

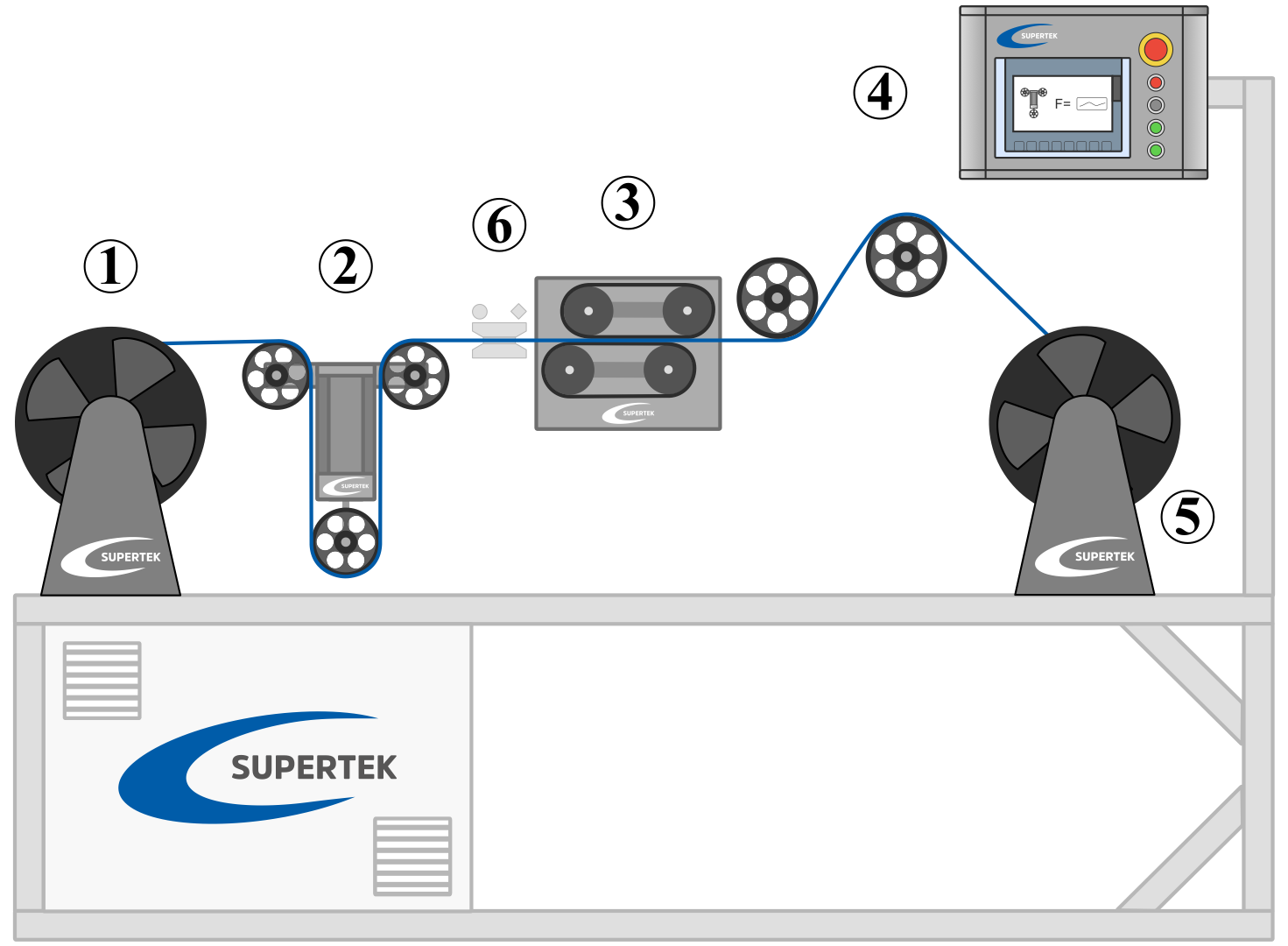

Drawing machine for fine wire.

🧵 Adapted for Every Diameter Range

Depending on the wire gauge, drawing is classified into:

-

Coarse drawing

-

Intermediate drawing

-

Fine and ultra-fine drawing

Each machine type is engineered to support optimal performance at the corresponding process stage. Particularly in non-ferrous metal applications, where precise control over geometry and surface quality is critical.

🔧 Fine Wire Drawing in Focus

Supertek’s systems are optimized for the demands of fine wire production. Cold forming not only changes the geometry of the wire, but also impacts mechanical properties such as tensile strength, hardness and ductility.

As demand for ultra-thin wires grows, Especially in electronics, sensor technology and medical devices, so does the need for equipment capable of exact tension control and perfect spooling. Supertek provides high-performance subsystems including:

-

Decoilers and payoff units

-

Precision tensioners

-

Traversing haul-offs and take-ups

-

Layer-accurate spoolers

⚙️ Engineered for Micro Precision

Our traversing take-up systems from the MW and SW series enable flawless, layer-by-layer spooling, essential for maintaining perfect coil structure and ensuring smooth unwinding in downstream processing.

The system shown features a fine wire drawing machine with a precision die and main capstan, designed specifically for ultra-thin materials. Two EDL 60 electromagnetic dancer units are integrated before and after the drawing stage to maintain stable wire tension throughout the process. Combined with Supertek’s advanced winding technology, this setup ensures precise coil formation and maximum reliability, from entry to final take-up.

Fine wire drawing - Process Diagram.

- Unwinder, pay-off unit

- Tension control, dancer

- Capstan

- HMI

- Take-up unit

- Drawing Die