INLINE MEASUREMENTS OF WIRE

In wire processing, inline measurement technology is a key component for achieving consistent and reproducible quality. Supertek integrates high-precision measurement systems directly into the production process, enabling continuous monitoring and evaluation of all relevant wire parameters, in real time and without interrupting production.

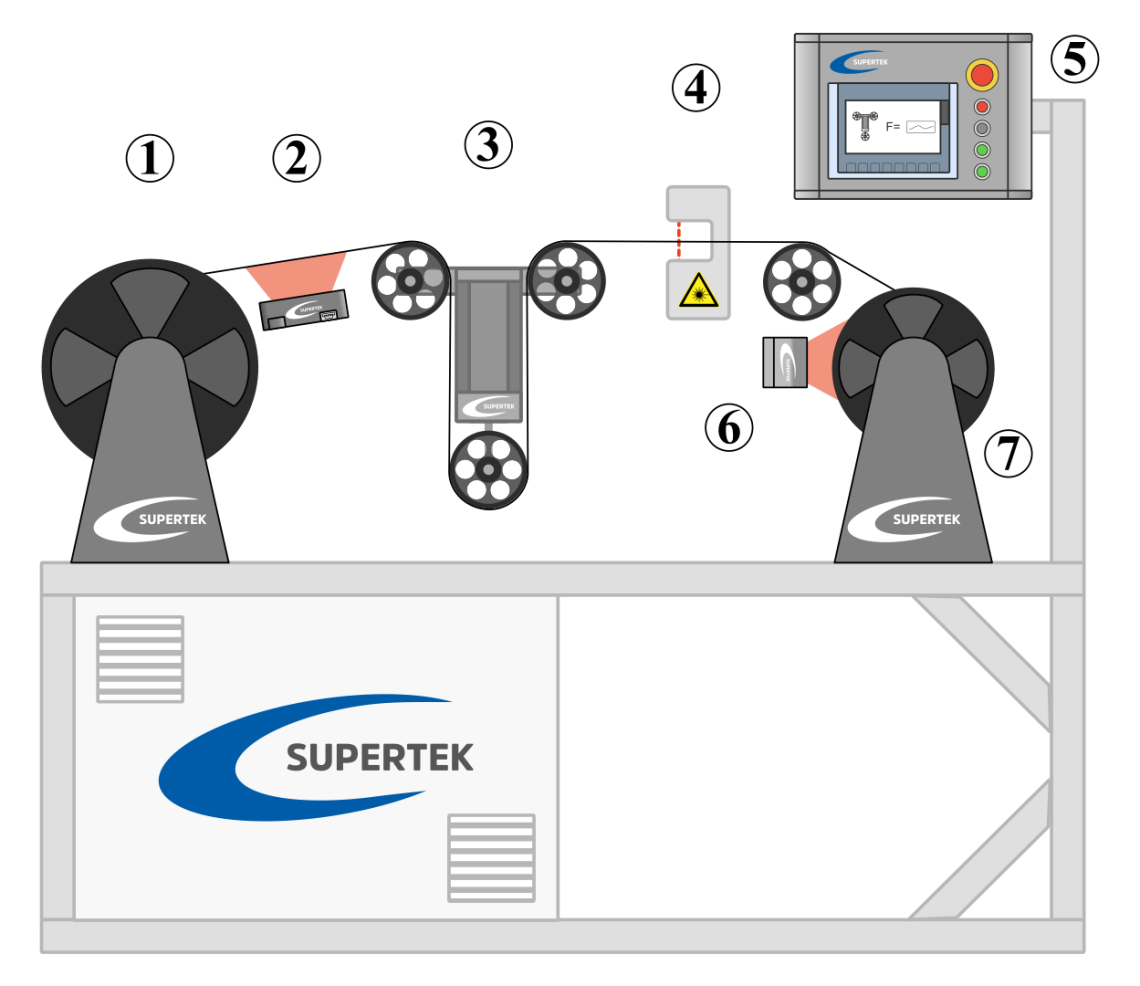

Wire monitoring - Rewinding machine.

Monitoring of Critical Wire Characteristics

The measurement solutions integrated into our systems reliably capture:

-

Diameter and ovality

-

Width and thickness of flat wires

-

Surface defects and structural anomalies

-

Concentricity, coating thickness and layer positions

-

Length, feed speed and piece count

All data is collected contact-free and inline, even at high production speeds and with sensitive materials, ensuring precise and stable operation.

🔍 Technology That Fits Seamlessly

All measurement components are individually configured for the specific application and fully integrated into the machine layout. This results in a compact, high-performance system, ideal for:

-

Automated feedback and closed-loop process control

-

Documentation and quality assurance

-

Integration with winding, cleaning or spooling systems

-

Custom requirements in terms of material, speed or environmental conditions

Process Diagram for testing and surface inspection of wire with a rewinding machine.

- Unwinder

- Position scanner

- Electromagnetic Dancer

- Measuring device, sensor head

- HMI

- Coil Scanner

- Rewinder

Because quality should never be left to chance.

With integrated inline measurement, Supertek provides reliable, actionable process data, embedded within the machine system, exactly where it matters.

Let’s develop the right solution for your line, together!