CLEANING REWINDING MACHINES

When precision matters, clean wire and optical fiber surfaces are essential. Supertek’s cleaning machines ensure optimal material preparation for downstream processes such as winding, coating, soldering or extrusion. Whether you process ultra-fine copper strands, optical fiber or solid industrial wire, Supertek delivers the cleaning performance your production demands.

Optical Fiber and Wire Cleaning Machine

✅ Professional Cleaning Technology for Demanding Applications

Supertek cleaning systems are designed to remove dust, drawing agents, oxidation, particles and residues from a wide range of wire materials, efficiently and gently.

We combine robust mechanical design, advanced cleaning technologies and precise process control to guarantee a consistently high surface quality.

Our systems support:

-

Mechanical cleaning (brushes, pads or wipers)

-

Solvent-based or aqueous chemical cleaning

-

Ultrasonic cleaning for sensitive wire types

-

Integrated drying and extraction units for clean, residue-free results

🧼 Compatible Wire and Fiber Types & Applications

Supertek wire cleaning machines are ideal for:

-

Copper, aluminum, optical fiber and precious metal wires

-

Flat and round wires in various diameters

-

Magnet wire preparation for coil and motor production

-

Pre-treatment for insulation, coating or lamination

-

Wire and optical fiber cleaning before high-precision winding or spooling

Clean wire and fiber is critical to clean performance.

With Supertek cleaning systems, you lay the foundation for quality, reliability and process stability, from the very first millimeter.

Contact us to explore the ideal cleaning solution for your application.

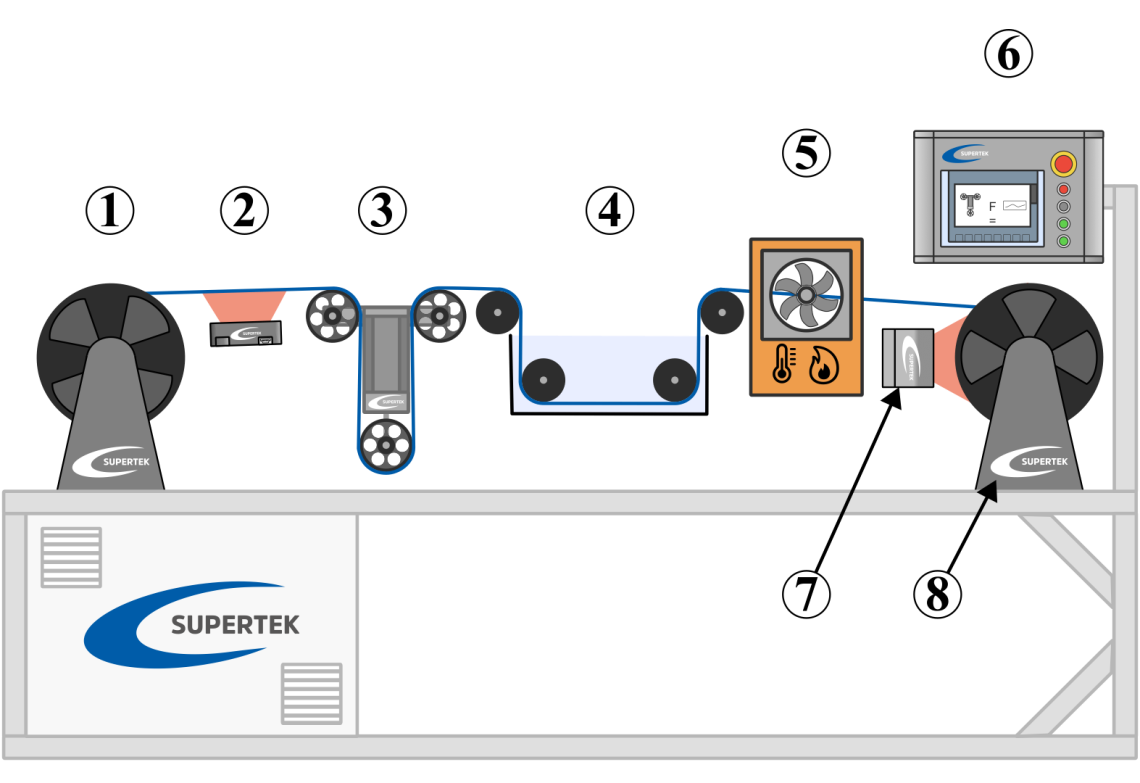

Wire and Fiber cleaning machine - Process Diagram.

- Decoiler / Unwinder

- Position scanner

- Tension control, e.g. electromagnetic dancer

- Wire cleaning process

- Drying

- HMI

- Spool scanner

- Spooler / Rewinder