UNWINDING MACHINE

Precision Payoff | Controlled Tension | Scalable Integration

Supertek unwinding systems are built for gentle and precise material handling, whether for ultra-fine wires, flat conductors or technical filaments. With intelligent tension control and modular architecture, these machines deliver reliable performance in coil processing, high-precision manufacturing and specialty applications.

🔄 Adaptable by Design

Each system is based on a modular platform, allowing full customization in terms of:

-

Number of unwinding stations

-

Spool size and geometry (bobbins, large coils, flat wire reels)

-

Tension range and regulation method

-

Target speeds and line layout

Thanks to flexible spool adapters and mechanical interfaces, integration into existing production lines is seamless, from standalone labs to automated manufacturing cells.

Precision Tension Control

– Electromagnetic and Closed-Loop

At the heart of each unwinding unit is a digitally adjustable electromagnetic dancer system. It ensures constant and stable wire tension, even under variable conditions and with highly sensitive materials. This level of control is essential for preventing overstretching, deformation or breakage, particularly in medical, aerospace, sensor or coil winding applications.

Optimized for Flat Wire and Compact Layouts

In space-constrained environments or with flat wire setups, optional traverse units allow for linear, low-deflection unwinding over short distances. This minimizes mechanical stress and guarantees smooth downstream feeding, especially when paired with high-speed winders, inline measurement or coating systems.

🧠 Smart Interfaces. Industry 4.0 Ready.

Equipped with a modern touchscreen HMI, the machine allows for:

-

Recipe-based operation

-

Quick parameter setup

-

Live process monitoring

-

Interfaces to MES, cloud or PLC systems

This makes Supertek unwinders ready for networked production environments and ensures long-term process reliability.

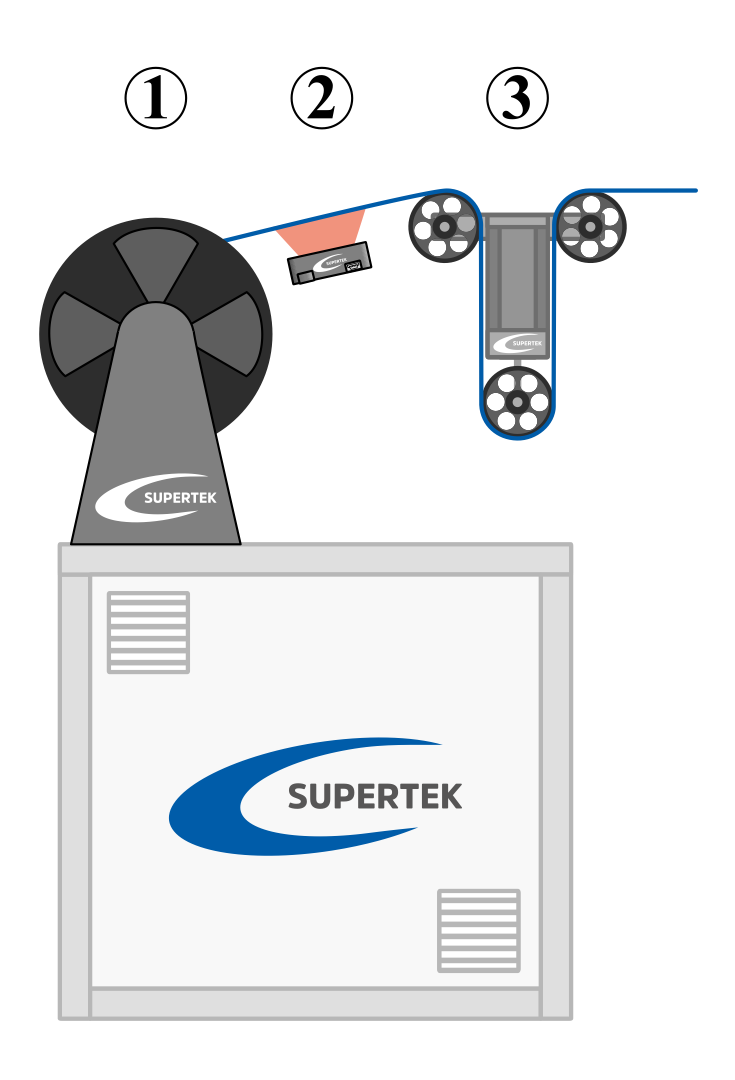

- Unwinder, optionally with traverse drive system

- Position Scanner for unwinding in a straight-line with the traverse drive system

- Tension control with Electromagnetic Dancer

🎯 Ideal for Applications Such As:

-

Wire feeding into winding, braiding or coating lines

-

Inline rewinding with quality inspection

-

Lab-based setups for material testing or pre-processing

-

Precision handling of sensor wire, magnetorquer coils or technical yarns

Built for sensitive materials, configured for your needs.

Supertek unwinding machines combine mechanical precision, intelligent control and maximum flexibility, for perfect payout, even under the most demanding conditions.

Tell us about your application and let’s build the right solution together.