REWINDING MACHINE

Supertek rewinding machines are designed for high-precision respooling of fine wires, filaments and technical fibers. Wherever sensitive materials and tight tolerances are involved, such as in electronics, sensor technology, fiber optics or advanced manufacturing environments, these systems ensure controlled, reliable results.

🔄 Respooling with Accuracy and Repeatability

Even ultra-thin wires and fragile filaments require clean winding layers, precise tension control, and gentle handling. Supertek rewinding systems are engineered to deliver exactly that – whether in laboratory setups, pilot lines, or full-scale industrial production.

Our winding technology supports:

-

Defined layer structures with smooth transitions

-

Dynamic tension control using integrated dancers and feedback systems

-

Custom spool compatibility (ED, MW, SW series and beyond)

-

Flexible layout options with single or multiple winding stations

⚙️ Key Functionalities at a Glance

-

Consistent winding patterns

High-quality, reproducible layouts with clean, stable layers -

Gentle material handling

Safe rewinding of ultra-fine wires, fibers, or specialty threads -

Optional tension regulation

Electromagnetic dancers and closed-loop feedback for active control -

Full configuration flexibility

Add-ons include pre-tensioning modules, position scanners, heating zones, or automatic cutters -

Operator-focused HMI

Touchscreen interface for intuitive parameter setup and real-time monitoring

🧩 Modular Design. Scalable Integration.

Each rewinding system is based on a modular machine architecture that adapts easily to evolving production needs. Whether a simple respooling unit or a multi-stage system with in-line inspection, Supertek machines are designed to grow with your process.

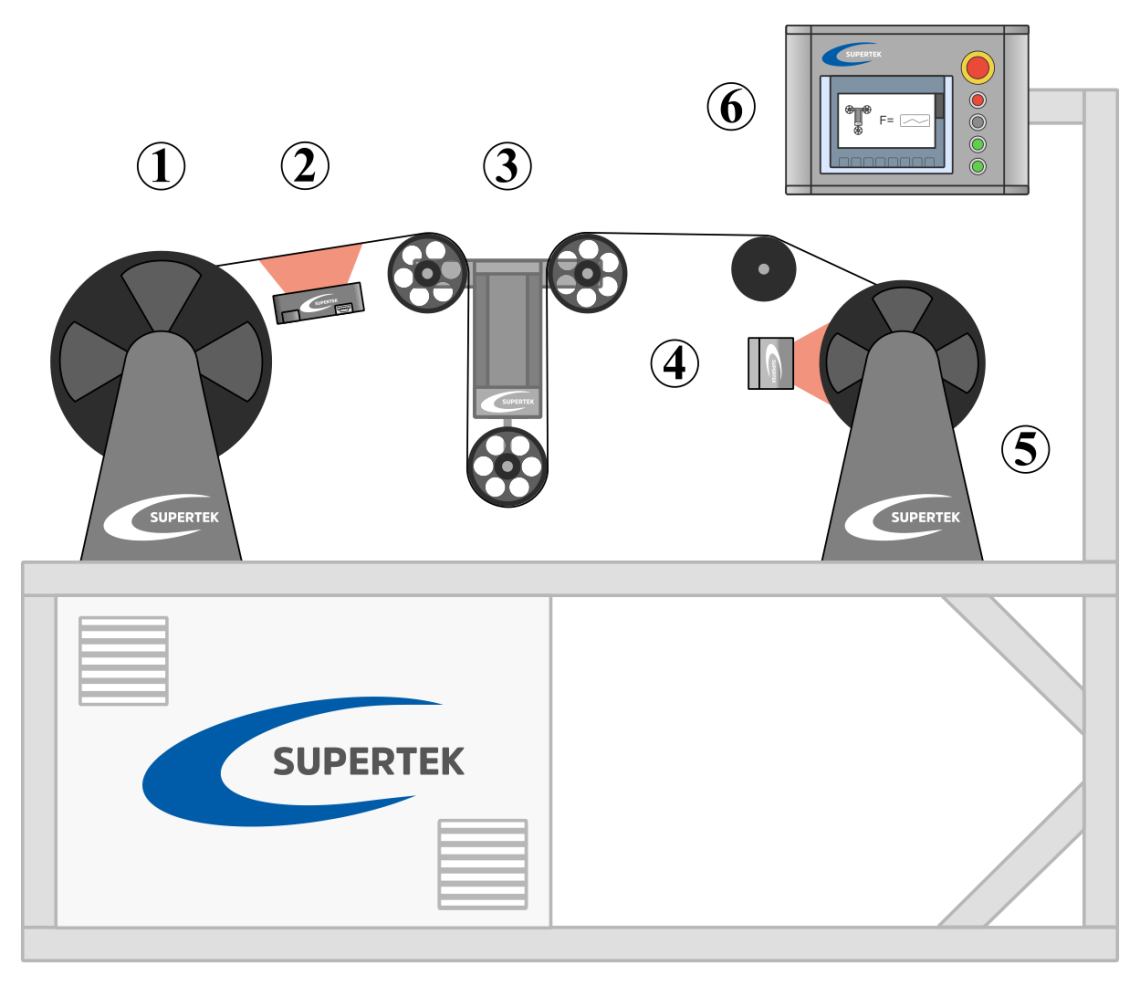

Process Diagram

- Decoiler

- Position scanner

- Electromagnetic dancer

- Coil scanner

- Rewinder

- HMI

High-Precision Respooling for Fine Wire and Delicate Materials

Each rewinding system is based on a modular architecture, allowing it to be easily expanded with additional winding stations, pre-tensioning units or visual inspection modules as needed. The process is controlled via an intuitive touchscreen HMI, enabling operators to configure all parameters, manage winding recipes and monitor real-time production data with precision.

Whether in high-volume manufacturing, research settings or specialized applications, Supertek rewinding machines deliver exceptional precision, consistent winding quality and full adaptability to both technical specifications and production demands.