COIL WINDER for TORQUE MEASUREMENT FLANGES

Targeted Winding | Consistent Tension | Direct-to-Flange Precision

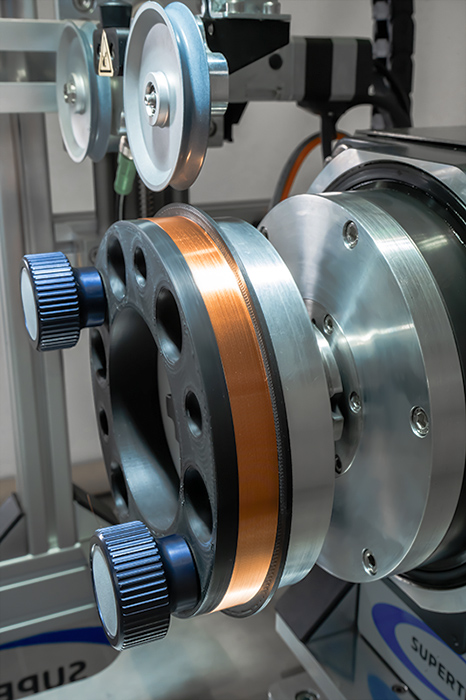

When coils must be wound directly onto torque measurement flanges, absolute precision is essential. Supertek’s precision coil winding system is designed for gentle, tension-controlled winding of fine wires, filaments or micro-coils, directly on rotational sensor elements such as torque transducers, couplings or sensor rings.

🔄 Direct Winding onto Funktional Components

This solution eliminates the need for intermediate carriers by winding directly onto the target geometry, ensuring:

-

Exact coil positioning on the flange surface

-

Uniform tension across all winding layers

- Whether used in torque measurement, strain gauge applications or rotational feedback systems, the setup delivers reliable results with micrometer accuracy.

Mechanical alignment and reproducibility for sensor calibration

⚙️ Controlled Process - From Start to Finish

Every aspect of the winding process is engineered for precision and repeatability. A high-resolution tension control system ensures that even the most delicate materials are guided smoothly and safely onto the flange surface. To accommodate different sensor designs, custom tooling is available for a wide range of flange sizes and geometries.

For applications requiring manual intervention or visual inspection, the machine features a slow-speed fine positioning mode, allowing the operator to make precise adjustments during the winding process. Additional options such as microscope support, a touchscreen HMI, and programmable winding patterns enhance both usability and control – making the system equally suitable for production environments and experimental setups.

This solution is ideally suited for the development and production of torque sensors, as well as for research and prototyping in the fields of rotational measurement, strain sensing, and precision coil placement on circular mechanical parts.